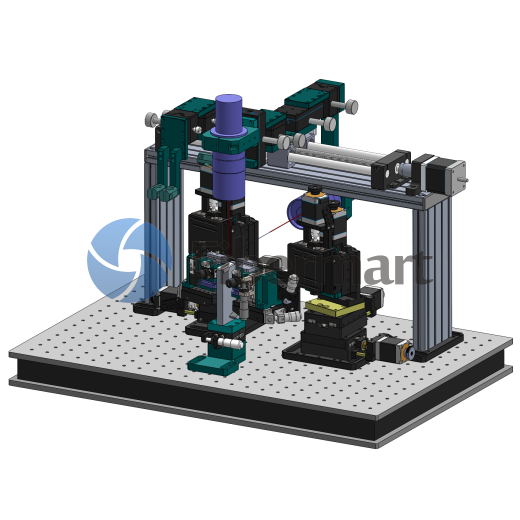

High Precision and Maneuverable Y waveguide Alignment Machine for Y waveguide Modelator manufacturing, 2 side 6 axis SemiAuto alignment with 100nm minimum accurate

The Sunma instrument company develops a new generation of manual and auto aligner for Y waveguide manufacturing. This product line features cost effective, high precision motion control capability with a compact mechanical design.

High quality components are used to assemble the system to guarantee high precision and repetitive motion applications.

The

precision of linear motion motion (Translational) X, Y, Z and rotationl

motion (Rotational)Pitch, Yaw, the Roll is 0.1 micron and 0.003 degree

respectively.

All the machinical handlers are our own

proprietary designs and made of high quality stainless steal to achieve

motion and temperature difference stability.

Handlers for fiber coupled array are equiped with touch sensors for accurate spacing control.

Versatile motion control software is both user friendly and powerful.

Its

modular design makes system upgrade and modification very simple.

Moreover, alignment procedure customerization is made possible by the

"workflow editor". Hence, users only just need to add and subtract the

preinstalled functions and input the corresponding parameters to

establish a particular alignment process.

2-day Free training, Installation &Calibration all for Free

Advantages:Trademarked Technology-5 Rs

Real Dual 6 degrees of freedom

Real Parallelism

Real Seamless Coupling

Real Gap Control

Real Performance

Low-cost, compact and fast SemiAuto-Alignment machine for Y waveguide pigtailing

Fast 1st light searching by near IR Camera(visible band to 1310nm) & rapid and automatic alignment

Fast automatic pitch-yaw parallelism adjustment

Accurate gap distance control by means of touch sensor

Precision motion platform of Newport delivers high accuracy and repeatability

Powerful software for easy operation

Total alignment time:100~125s

In addition to automatic, as well as semi-automatic and manual options

• Fiber optical gyroscope (FOG)

• Fiber Optic Current Sensor (FOCS)

• Hydrophones and other optical fiber sensing fields

Translation(X-Y-Z axis) | |

Component | Sunma VP-25XA or VP-25XL |

Travel Range(mm) | XYZ: 25mm |

Resolution(μm) | 0.1 (VP-25XA), 0.05 (VP-25XL) |

Bi-directional Repeatability(μm) | 0.15 |

On-axis Accuracy(μm) | 1 |

Maximum(mm/s) | 25 |

Rotation(PitchθX-YawθY-RollθZ axis) | |

Component | Newport CMA-PP or TRA-PPD |

Travel Range(mm) | θX:6mm, θY:6mm, θZ:12mm (±3°) |

Resolution(μm) | 0.3 (CMA-PP), 0.1 (TRA-PPDL) |

Bi-directional Repeatability(μm) | 2 |

Maximum(mm/s) | 0.4 |

Tooling | |

(Patent Pending)Touch sensor embedded Universal Fiber Array Holder × 2 | |

(Patent Pending)Touch sensor accuracy(μm)< 2 | |

Universal 1×N Splitter Holder(1×2 to 1×64)× 1 | |

Vacuum AWG Holder × 1 | |

Vision | |

Camera Type | CCD×2, IR Cam×1 for 1st light searching |

Lighting | Software Controlled LED Bar Light |

Machine vision | Image ssen through PC Vision Card |

Image Resolution | <3μm/Pixel(depends on Mag. X of lens) |

Motion | 100mm(according to request) |